Why Electronic Leak Detection is a Game-Changer for Hidden Leaks

Electronic leak detection is a non-destructive testing method that uses electrical current to pinpoint breaches, holes, and seam voids in waterproof membranes and roofing systems. This advanced technology works by completing an electrical circuit through water that seeps through leaks, allowing technicians to locate even the smallest damage without tearing up floors, walls, or roofs.

Key Electronic Leak Detection Methods:

- Low-Voltage Testing – Uses wet surfaces and scanning platforms to trace electrical flow through breaches

- High-Voltage Testing – Employs dry membrane testing with spark detection at leak points

- Vector Mapping – Traces electrical paths to pinpoint exact leak locations

- Continuous Monitoring – Embedded sensor systems for 24/7 leak detection

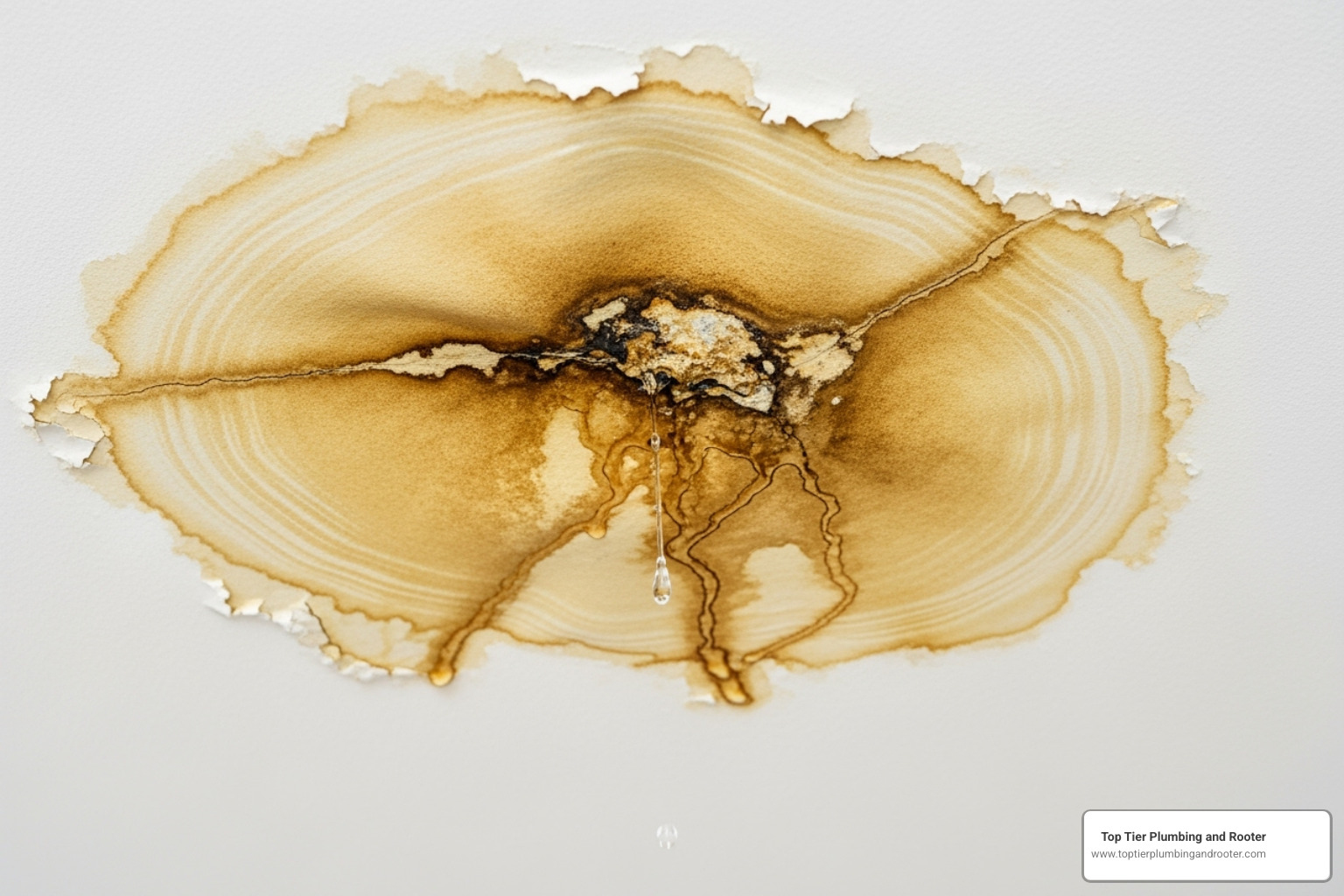

Hidden leaks cause billions in property damage every year. Traditional methods like flood testing or infrared thermography often miss small leaks or require destructive investigation. Electronic leak detection changes this by offering precise leak location with minimal disruption.

Research shows that 71% of membrane damage is caused by stones and most holes are tiny – between 0.5mm to 20mm in diameter. These pinhole leaks are nearly impossible to spot visually but can cause massive water damage over time.

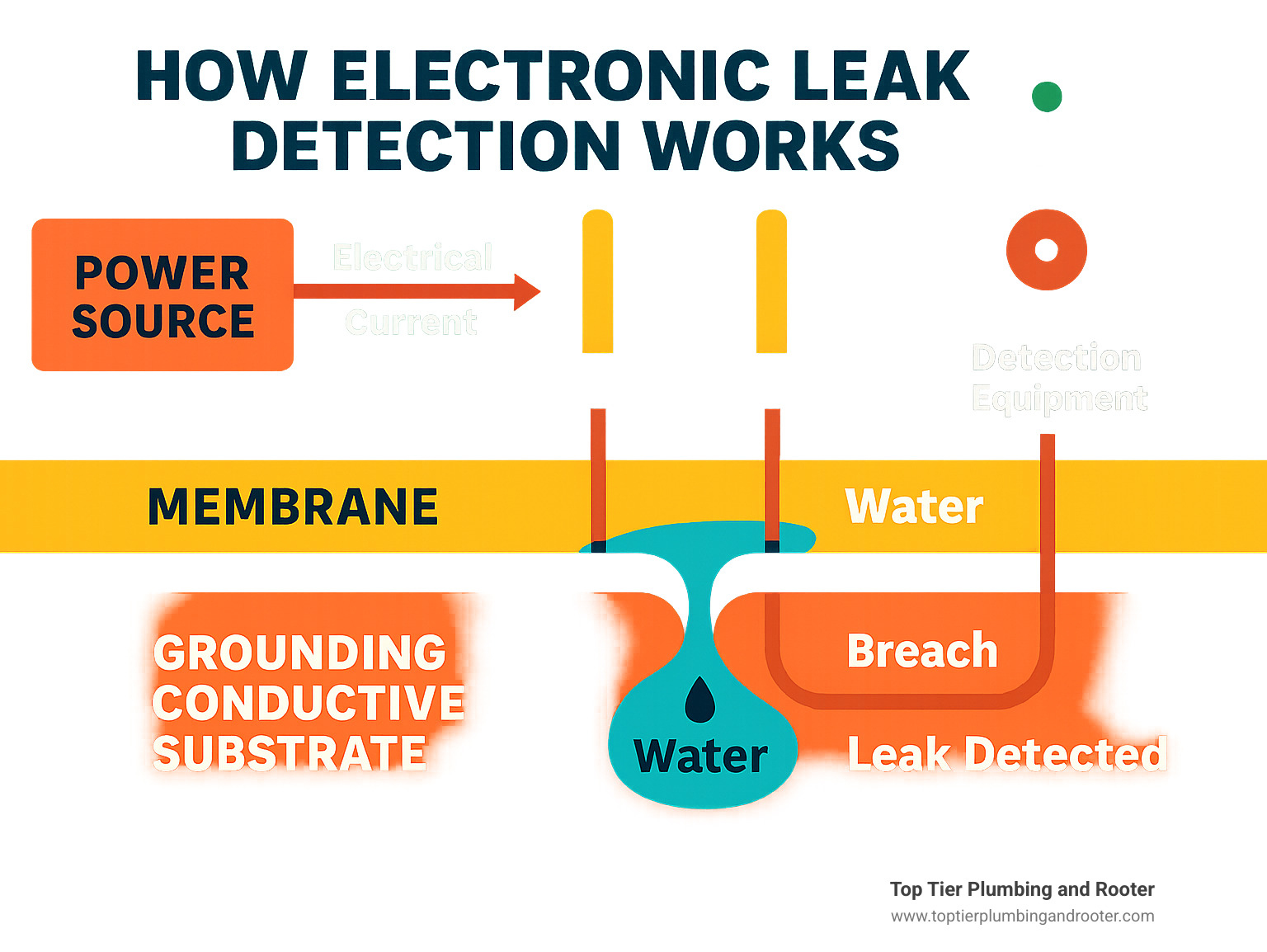

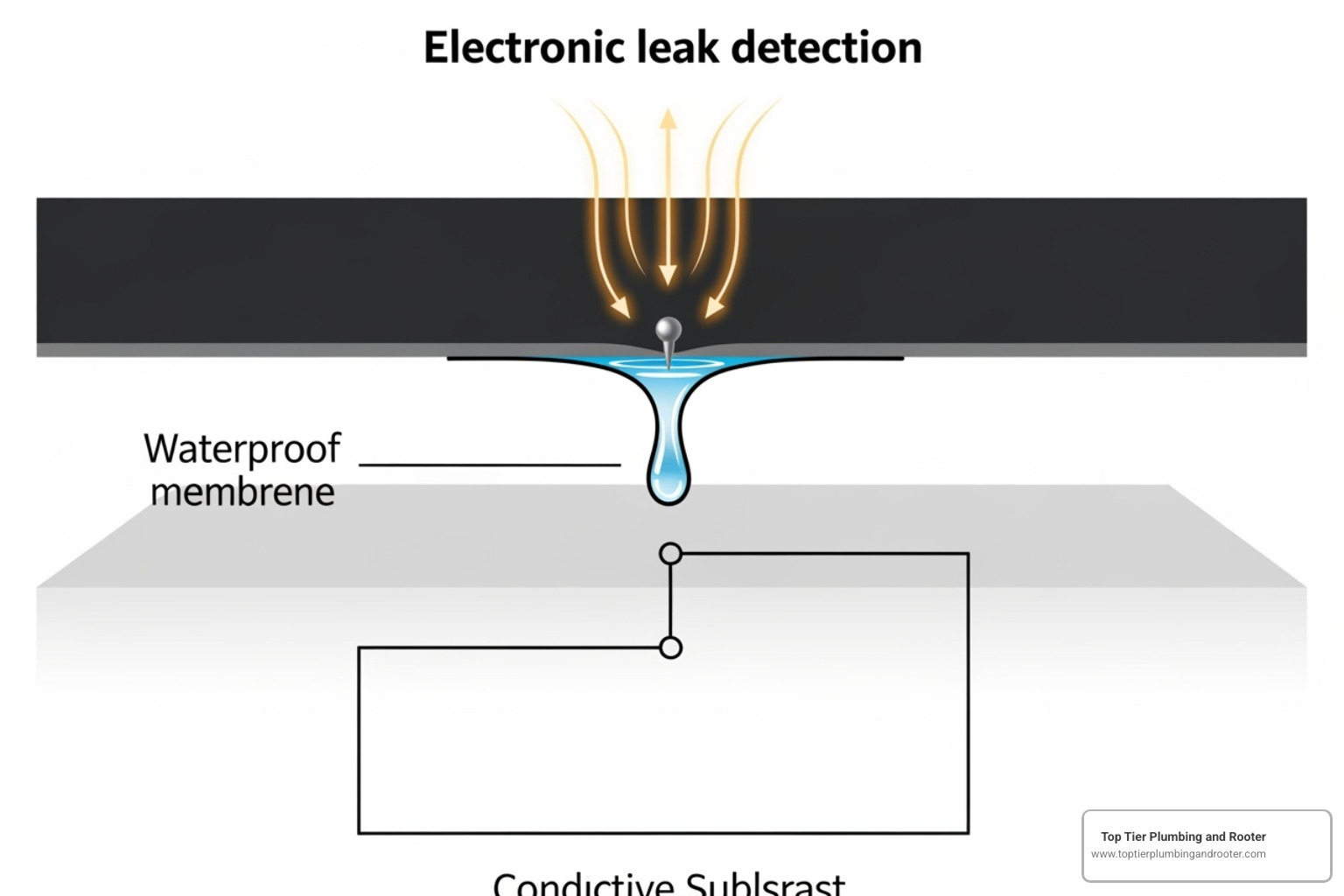

The technology works on a simple principle: waterproof membranes block electrical current, but water conducts electricity. When a leak allows water to reach a grounded conductive surface below the membrane, it completes an electrical circuit that triggers an alarm.

How Electronic Leak Detection Works: The Science Behind the Scan

The science behind electronic leak detection is surprisingly straightforward. It uses electricity to solve the mystery of hidden leaks.

A waterproof membrane acts as an electrical insulator, blocking the flow of electricity. Underneath this barrier lies a conductive substrate—typically concrete or metal decking—that can carry an electrical current. When the membrane is intact, these two layers remain electrically isolated.

But when a breach occurs, even a tiny pinhole, water becomes the missing link. Since water conducts electricity, it creates a pathway between the surface and the grounded substrate below, completing an electrical circuit and triggering the detection equipment’s alarm.

Technicians apply a small electrical charge to the membrane surface using specialized probes or scanning equipment. As they move across the area, the system monitors for changes in electrical resistance. When water from a leak creates that connection to the conductive substrate, the equipment immediately alerts the technician with visual and audible signals.

This precision allows us to pinpoint leaks without the guesswork of traditional methods. For more insights into comprehensive leak detection approaches, check out our guide on Detecting and Repairing Pipe Leaks: A Comprehensive Guide.

The Role of a Conductive Medium

Not all building surfaces are naturally ready for electronic leak detection. Wood substrates and some insulation materials don’t conduct electricity well. This is where conductive mediums come in.

These specialized materials create the necessary electrical pathway. Conductive primers with carbon black can be applied to non-conductive surfaces, while embedded mesh made from stainless steel or aluminum provides another effective solution. These materials turn any surface into a suitable testing ground.

This preparation is crucial for accurate tests during installation and maintenance. It ensures quality control measures can be implemented from the start, catching potential problems before they become expensive headaches.

Key Components of an ELD System

Every electronic leak detection system has several key components. The power source is usually a portable battery pack.

The probes or rollers make direct contact with the membrane surface. These can be handheld wands for detailed work or larger scanning platforms for wide areas. Specialized wands are useful for vertical walls and tight spaces.

A ground wire connects the system to a reliable ground point, completing the circuit when a leak is present. The signal processing unit is the system’s brain, analyzing electrical signals to determine when a breach is detected.

When a leak is found, visual and audible alerts like LED lights, screen displays, and beeps guide the technician directly to the problem area, eliminating guesswork.

A Closer Look at Electronic Leak Detection Methods

When it comes to electronic leak detection, there isn’t a single method that works for every situation. Choosing the right approach is crucial for accurate results.

Industry guidelines from organizations like ASTM International (ASTM Guide D7877-14 and ASTM D8231-19) ensure consistent, reliable testing across the board.

Choosing the right method depends on the membrane type, whether it’s a horizontal or vertical surface, and if water can be safely applied. The two main approaches—low-voltage and high-voltage electronic leak detection—each have specific uses.

| Feature | Low-Voltage ELD | High-Voltage ELD (Spark/Holiday Testing) |

|---|---|---|

| Water Requirement | Yes, requires a wet membrane surface | No, requires a completely dry membrane surface |

| Membrane State | Wet | Dry |

| Voltage Range | Relatively low (e.g., 40V) | High (1,000 to 30,000 volts DC) |

| Conductive Path Req. | Requires a continuous electrical path to ground | Requires a continuous electrical path to ground |

| Risk of False Positives | Lower, due to reliance on water’s conductivity | Higher, sensitive to surface contaminants, moisture |

| Safety Concerns | Minimal, very low risk of injury | Higher, risk of electrical shock, membrane damage |

| Best Use Case | Precise leak location, quality control, forensic | Rapid scanning for large defects, initial integrity |

| Compatibility (Semi-Cond.) | Specific low-voltage systems can test semi-conductive membranes with conductive primers | Generally not compatible with semi-conductive membranes (e.g., black EPDM, fluid-applied) |

The Basics of Low-Voltage electronic leak detection

Low-voltage electronic leak detection is incredibly precise and methodical. This approach requires the membrane surface to be wet. The water acts as a conductor, flowing through any breach and creating an electrical pathway that our equipment can follow.

Vector mapping is one of the most sophisticated techniques. A perimeter wire is laid around the test area and connected to a pulsating low-voltage generator, creating an electrical field. A technician then uses a two-probe system to follow the electrical flow like breadcrumbs directly to the leak source.

Scanning platforms use specialized pads or rollers that glide across the wet membrane. These systems are workhorses for quality control on new installations, with some advanced platforms testing up to 3,700 square meters in a day.

The beauty of low-voltage methods is their precision, pinpointing leaks down to a single millimeter. This allows for highly targeted and efficient repairs without guesswork.

Understanding High-Voltage electronic leak detection

High-voltage electronic leak detection—also known as spark or holiday testing—takes a different approach. It’s like a security scanner, quickly identifying problems over large areas.

This method works on completely dry membranes and uses 1,000 to 30,000 volts. A technician passes a metal “broom” or brush connected to the high-voltage source over the dry membrane. The system is grounded to the conductive substrate below.

When the brush encounters a breach, hole, or thin spot (a “holiday”), the high voltage creates a visible and audible spark through the defect.

High-voltage testing excels at rapidly scanning large areas and is excellent for initial integrity checks. However, the membrane must be bone dry, and there’s a higher risk of false positives if the surface isn’t clean. Safety is also a major concern due to the high voltages, so trained personnel and proper protective equipment are essential.

A key limitation is that some conductive materials like black EPDM or certain modified bituminous membranes can cause false readings, making them better suited for low-voltage methods.

The Advantages of ELD Over Traditional Methods

For decades, finding a hidden leak meant messy, expensive, and destructive options. Traditional methods often feel like a frustrating guessing game.

- Flood testing involves flooding an area with water. This can cause more damage than the original leak and only confirms that a leak exists, without pinpointing its location.

- Infrared thermography uses thermal cameras to find collected moisture, but it can’t pinpoint the leak’s actual source. The entry point could be far from the visible wet spot.

- Destructive testing means tearing into walls, floors, or ceilings until the problem is found, often leading to unnecessary damage and repairs.

Electronic leak detection changes everything. Instead of guesswork and demolition, this technology provides precise leak location, often accurate to within inches. It’s completely non-destructive, so we won’t tear up your property searching for the problem. Low-voltage methods use minimal water, and high-voltage testing requires no water at all, preventing additional damage during the detection process.

The beauty of electronic leak detection is its precision. When we find the exact location of a breach, repairs become targeted and efficient. Instead of replacing an entire section of roofing or waterproofing, we can fix just the problem area. If you’re noticing unexplained dampness or water stains, these could be signs of hidden leaks. Learn more about identifying these problems in our guide: Signs You Need a Plumbing Inspection: How to Spot Hidden Issues Before They Escalate.

Preventing Costly Damage and Repairs

Most leaks start incredibly small. Research shows that 71% of membrane damage is caused by stones, and the majority of holes are tiny—between 0.5mm to 20mm in diameter. These pinhole leaks, often invisible to the naked eye, can cause thousands of dollars in damage over time as water seeps in day after day.

Electronic leak detection catches these problems while they’re still manageable. By finding leaks early, we prevent the domino effect that turns a simple repair into a major renovation. Instead of dealing with extensive water damage, structural repairs, and mold remediation, you’re looking at a quick, targeted fix.

The technology is sensitive enough to detect breaches that are practically invisible. This early detection capability means we’re not just finding leaks—we’re preventing disasters, protecting your assets, and helping you avoid the stress and expense of major water damage.

Quality Assurance for New Construction

Electronic leak detection is also a powerful tool for ensuring new waterproofing systems are installed correctly. When contractors install a new roof or membrane, ELD testing can verify the installation’s integrity before any protective layers are applied.

This proactive approach offers several benefits:

- Verifying installation integrity catches manufacturing defects or installation errors while they are easy and inexpensive to fix.

- Contractor accountability becomes clear-cut with objective testing results that show whether work meets specifications.

- Preventing future issues by fixing small problems immediately stops them from becoming major headaches.

For property owners, this testing provides genuine peace of mind. Knowing your new waterproofing system has been thoroughly tested gives you confidence in your investment.

Common Applications and Industry Best Practices

Electronic leak detection has become an indispensable tool across a wide range of industries and applications where waterproofing integrity is paramount. While we at Top Tier Plumbing and Rooter specialize in residential plumbing services in Riverside and San Bernardino counties, the principles of ELD extend to many critical areas.

You’ll find ELD technology being used for:

- Roofing Systems: Especially flat roofs, green roofs, and plaza decks where leaks can be notoriously difficult to find.

- Waterproofing Membranes: In basements, tunnels, and below-grade structures to prevent water intrusion.

- Plaza Decks and Balconies: Where waterproofing is essential to protect occupied spaces below.

- Swimming Pools and Water Features: To detect leaks in liners and ensure water retention.

- Containment Liners: Such as those in landfills, reservoirs, and industrial ponds, where preventing leakage is critical for environmental protection.

The versatility of ELD makes it a preferred method for ensuring the long-term performance and safety of various structures.

Following Industry Standards

To ensure that electronic leak detection is reliable and accurate, adhere to established industry standards and best practices. Organizations like ASTM International have developed specific guidelines, such as ASTM Guide D7877 and ASTM D8231, which outline the correct procedures for performing ELD tests.

These standards cover everything from proper surface preparation and environmental conditions to equipment calibration and reporting. By following these guidelines, we ensure:

- Test Accuracy: The results are consistent and truly reflect the integrity of the membrane.

- Repeatable Results: Tests performed by different technicians or at different times yield similar outcomes.

- Qualified Technicians: Ensures that the professionals performing the tests are properly trained and knowledgeable in ELD methodologies.

Just as you wouldn’t trust your home’s complex plumbing system to an amateur, you shouldn’t trust advanced leak detection to anyone but a trained professional. Attempting complex tasks like ELD without proper knowledge can lead to inaccurate results or even damage. We always recommend hiring experts for specialized services. For insights into why expertise matters, read about The Hidden Dangers of DIY Plumbing: Why You Should Hire a Professional.

Ensuring Reliable and Accurate Results

Achieving reliable and accurate results with electronic leak detection goes beyond simply owning the equipment. It requires careful attention to detail and a thorough understanding of the technology.

Key practices include:

- Proper Surface Preparation: The membrane surface must be clean and free of debris that could interfere with the electrical current. For low-voltage tests, it needs to be uniformly wetted.

- Valid Ground Connection: A strong, reliable connection to the building’s ground or an appropriate ground rod is paramount. Without it, the electrical circuit cannot be properly completed, leading to inaccurate or missed detections.

- Choosing the Right Method: As we discussed, low-voltage and high-voltage methods have different strengths and weaknesses. Selecting the appropriate technique for the specific membrane type and site conditions is crucial. For instance, testing black EPDM, which can be semi-conductive due to carbon black, often requires specialized low-voltage systems or the use of conductive primers.

- Understanding Limitations: No technology is foolproof. Professionals understand the limitations of ELD, such as challenges with very deep overburden (which can make it difficult for the electrical signal to penetrate) or the potential for false positives if conditions aren’t ideal.

- Professional Service: The most critical factor is engaging experienced and reputable professionals. Their expertise ensures tests are performed correctly, results are interpreted accurately, and any limitations are properly addressed.

Frequently Asked Questions about Electronic Leak Detection

We know that electronic leak detection can seem complex. Here are answers to the most common questions we hear from homeowners and property managers.

What are the limitations of ELD?

While electronic leak detection is powerful, it does have some limitations.

- Conductive Membranes: Some materials, like black EPDM or certain fluid-applied membranes, contain carbon black that makes them semi-conductive. This can interfere with standard testing methods and cause false readings unless specialized primers or compatible ELD systems are used.

- Deep Overburden: ELD works best with direct access to the membrane or with a thin layer of material on top. Thick layers of concrete, pavers, or deep soil can block the electrical signal, making tests inconclusive according to the ASTM D-8231-19 standard. It’s best to test before any covering is installed.

- Conductive Path: The method requires a continuous path for water to flow from the leak to a grounded surface. If water can’t reach the ground connection or the substrate isn’t conductive, a leak might be missed.

- False Positives: Improper testing, such as uneven surface wetting, contamination, or incorrect equipment setup, can trigger false alarms. This is why professional expertise is essential.

What are the safety considerations when using ELD?

Safety is our top priority when performing electronic leak detection. Most methods are quite safe when handled by trained professionals.

- Low-voltage methods are generally very safe, using minimal electrical current with virtually no risk of injury.

- High-voltage spark testing uses up to 30,000 volts and requires extensive safety training and strict protocols. Direct contact with the equipment or testing in wet conditions can cause severe electrical shock.

- Proper grounding is crucial for both accuracy and safety. An incorrect ground connection can lead to inconsistent readings or create hazardous conditions.

- Our technicians always use appropriate personal protective equipment (PPE), such as insulated gloves and safety boots, during high-voltage testing and follow all manufacturer guidelines.

The bottom line is that hiring trained professionals is the safest and most reliable approach.

Can ELD be used for continuous monitoring?

Yes, electronic leak detection has evolved to include sophisticated continuous monitoring systems.

Embedded sensor systems are installed beneath the waterproofing membrane during construction, acting like a built-in security system for your roof or foundation. These systems include sensor grids connected to a central monitoring unit.

The grids provide 24/7 monitoring of your waterproofing integrity. The moment water breaches the membrane and contacts a sensor, the system detects the change in electrical conductivity.

Real-time alerts are a game-changer. Instead of finding a leak weeks or months later, you get an immediate notification when damage occurs. This allows for rapid response and repair, often preventing any significant damage.

Continuous monitoring systems are ideal for critical facilities like data centers, hospitals, museums, and high-end residential properties where water damage could be catastrophic. It catches problems when they are small, manageable, and inexpensive to fix.

Conclusion

When it comes to protecting your home from the silent threat of hidden leaks, electronic leak detection truly represents a breakthrough in modern technology. This sophisticated, non-invasive approach has revolutionized how we find and fix water intrusion problems, offering the kind of precision that was simply impossible with traditional methods.

Think about it – no more guesswork, no more tearing up perfectly good floors or walls just to chase down a mysterious leak. Electronic leak detection pinpoints breaches, holes, and seam voids in waterproofing membranes with remarkable accuracy, often down to the exact millimeter. Whether we’re talking about quality assurance for new construction or preventing costly damage in your existing home, ELD gives you a proactive shield against water damage.

At Top Tier Plumbing and Rooter, we’ve seen the heartbreak that hidden water leaks can cause. That mysterious wet spot on your ceiling, the musty smell that just won’t go away, or worse – finding extensive water damage that’s been happening behind the scenes for months. We know how frustrating it can be when traditional methods fall short or require destructive investigation.

That’s why we’re committed to staying at the forefront of advanced technology like electronic leak detection. Our team serves homeowners throughout Riverside and San Bernardino counties with cutting-edge diagnostic tools that get to the root of the problem quickly and accurately. We believe in doing things right the first time, which means using the best technology available to protect your most valuable investment – your home.

Don’t let hidden leaks continue their destructive game of hide-and-seek with your property’s structural integrity. Accept the benefits of this technology and enjoy the peace of mind that comes with knowing exactly where problems exist and how to fix them efficiently.

For expert assistance with stubborn or hidden water leaks, trust our professionals to provide accurate diagnostics and effective Pipe Leak Repairs. We’re here 24/7 to help protect your home with the most advanced leak detection methods available.